CNC Machining Services

Precision Manufacturing, From Prototype to Production

Precision at Scale, From Prototype to Production

CNC Milling

CNC Turning

Production Machining

When your project requires volume, we deliver. Our production machining services are designed for efficient batch manufacturing of hundreds to thousands of units. With streamlined workflows, material traceability, and automated process monitoring, we minimize lead times while maximizing throughput and consistency—perfect for just-in-time supply chains and recurring part orders.

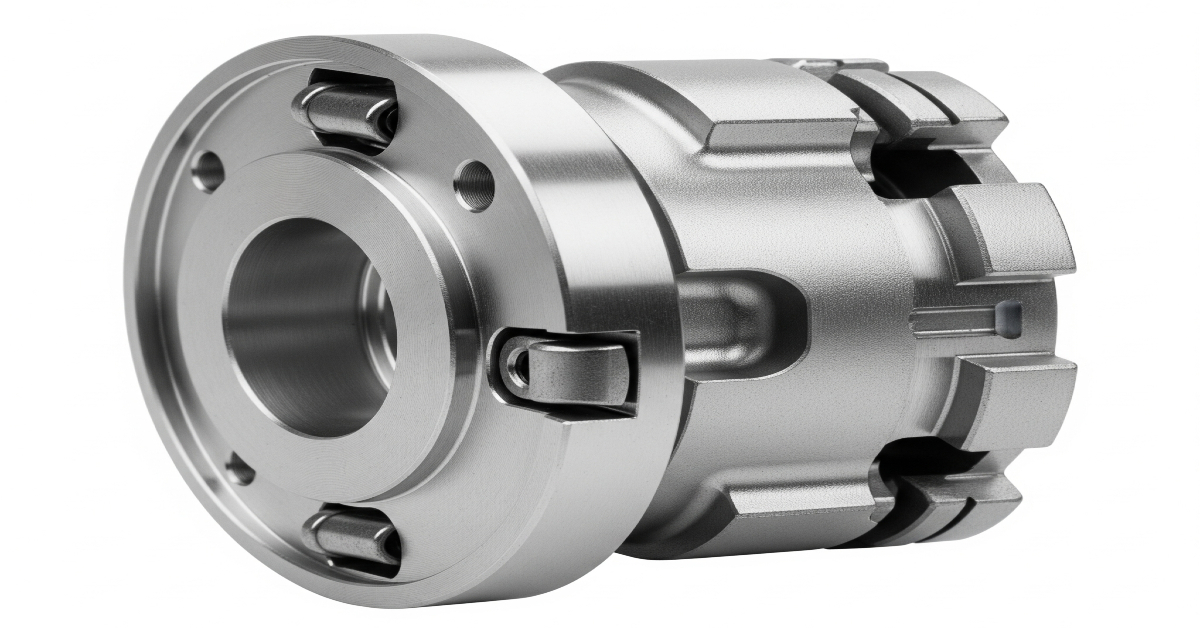

Precision Machining

Tolerances that leave no room for error. We specialize in tight-tolerance machining for industries like medical, aerospace, and robotics where even a micron matters. Through a combination of precision tooling, skilled machinists, and calibrated inspection equipment, we ensure every part meets its exact requirements—every time.

Threading Options

We offer a wide range of threading options including standard UNC/UNF, metric, pipe threads, and custom thread profiles. Internal and external threading is supported across multiple diameters and materials, enabling seamless assembly with other components and systems. Our threading expertise ensures proper fit, strength, and function in all critical applications.

Finishing Options

Enhance functionality and aesthetics with our comprehensive finishing options. From anodizing, powder coating, and bead blasting to chemical passivation and plating, we provide finishing services that meet your application’s durability, appearance, and corrosion-resistance needs. We also offer post-machining inspection and documentation as part of our quality control.

Materials We Work With

Metals

Our metal machining capabilities support high-performance parts for industries where strength, durability, and precision are essential.

Aluminum

Aluminum is a top choice for CNC machining thanks to its lightweight nature, excellent machinability, and strong thermal and electrical conductivity. Common grades like 6061-T651, 7075-T651, and 2024-T351 offer a reliable combination of strength, corrosion resistance, and cost-efficiency.

Brass

Brass offers excellent machinability, corrosion resistance, and thermal conductivity. It’s ideal for components requiring low friction and precision, such as fittings and gears.

Copper

Copper features exceptional electrical and thermal conductivity, making it ideal for electrical components and heat exchangers. It’s also highly corrosion-resistant.

Stainless Steel

Stainless steel is known for its strength, corrosion resistance, and clean appearance. It’s commonly used in medical, food-grade, and high-strength applications.

Steel Alloy

Steel alloys provide superior strength and wear resistance, making them suitable for structural, automotive, and heavy-duty industrial components.

Mild Low Carbon Steel

Mild steel is affordable and easy to machine and weld. It’s a common choice for general-purpose mechanical parts.

Titanium

Titanium is lightweight, corrosion-resistant, and extremely strong, making it ideal for aerospace, medical, and high-performance applications.

Plastics

- ABS

- Acetal / Delrin

- CPVC / PVC

- HDPE / LDPE

- Nylon

- PEEK

- PEI (Ultem)

- PET / PMMA (Acrylic)

- Polycarbonate

- Polypropylene / Polystyrene

- PPSU / PSU

- PTFE (Teflon)

Industries We Serve

Why Choose Universal Prototype for CNC Machining?

At Universal Prototype, we combine precision engineering with production scalability to deliver CNC machining solutions that meet the most demanding requirements. From prototyping to mass manufacturing, our advanced capabilities and customer-first approach ensure exceptional results every step of the way.

- Advanced multi-axis machining centers for complex geometries

- Support for low-volume prototyping and high-volume production

- Tight tolerances and certified quality control processes

- Diverse material compatibility—metals, plastics, alloys

- Fast lead times and competitive global pricing

- Scalable infrastructure to meet growing demands