Injection Molding Services

Engineered for Precision. Built for Scale.

Comprehensive Capabilities, From Prototype to Production

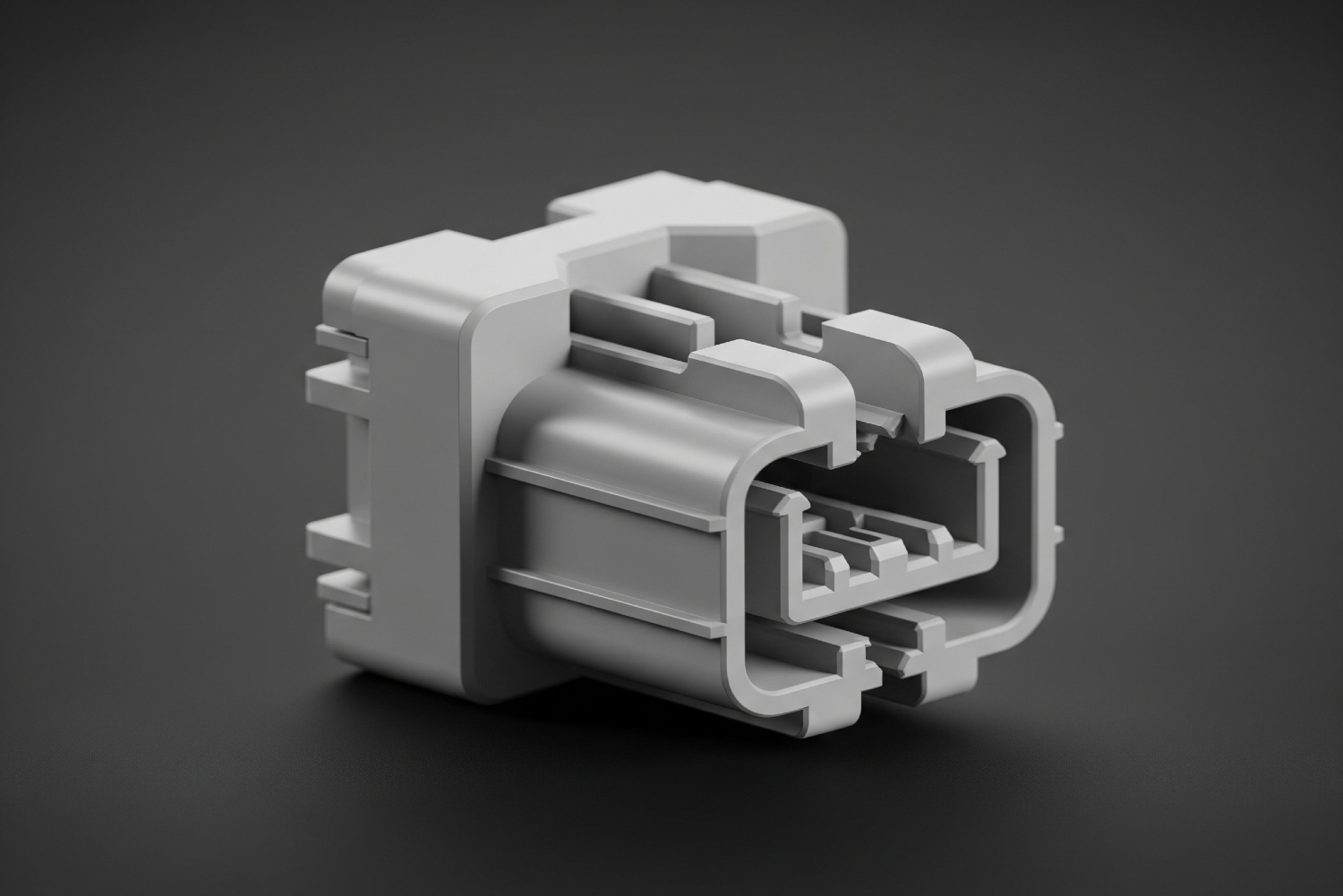

Plastic Injection Molding

Insert Molding

Overmolding

Unmatched Quality and Precision

Precision starts with quality. Every molded part goes through rigorous inspection, dimensional verification, and process control to meet your specifications and industry standards. From first article to final batch, quality is built into everything we do.

Prototyping to Mass Production—Seamlessly Integrated

Accelerate your design cycle with our rapid prototyping capabilities. Whether you're testing fit and function or validating form and material, we offer quick-turn prototypes using the same molding techniques and materials used in production.

Secondary Operations & Finishing Services

Add value and functionality to your molded parts. We offer a range of post-molding services including ultrasonic welding, laser marking, pad printing, assembly, and custom finishing—streamlining your production workflow and reducing turnaround time. Complete your molded parts with additional value-added services, including:

- Ultrasonic welding

- Pad printing & laser engraving

- Threading & inserts

- Custom finishing options

Injection Molding Materials

Thermoplastics

Our extensive thermoplastic options are suitable for a broad range of industries—from automotive and aerospace to consumer electronics and medical devices.

Available Thermoplastics Include:

- ABS

- Acetal (Copolymer & Homopolymer/Delrin)

- ETPU

- HDPE / LDPE / LLDPE

- LCP (Liquid Crystal Polymer)

- Nylon (PA)

- PBT

- PC/ABS

- PC/PBT

- PEEK

- PEI (Ultem)

- PET / PETG

- PMMA (Acrylic, Plexiglas)

- Polycarbonate

- Polypropylene (PP)

- PPA

- PPE/PS

- Polystyrene (PS)

- Polysulfone (PSU)

- TPU (Thermoplastic Polyurethane)

Thermosets

When durability, flexibility, or specialized resistance is required, we offer premium thermoset materials, including:

Available Thermosets Include:

- Standard Silicone (30, 40, 50, 60, 70 durometers)

- Medical-Grade Silicone

- Optical-Grade Silicone

- Fluorosilicone (fuel & oil resistant)

Industries We Serve

Why Choose Universal Prototype for Injection Molding?

- Global capabilities with fast lead times

- Expert engineering and design support

- Flexible order quantities—from one to thousands

- Competitive pricing and consistent quality

- Scalable solutions for growing businesses