3D Printing Services

Rapid, Precise, and Scalable Additive Manufacturing

Agile Manufacturing, From Concept to Production

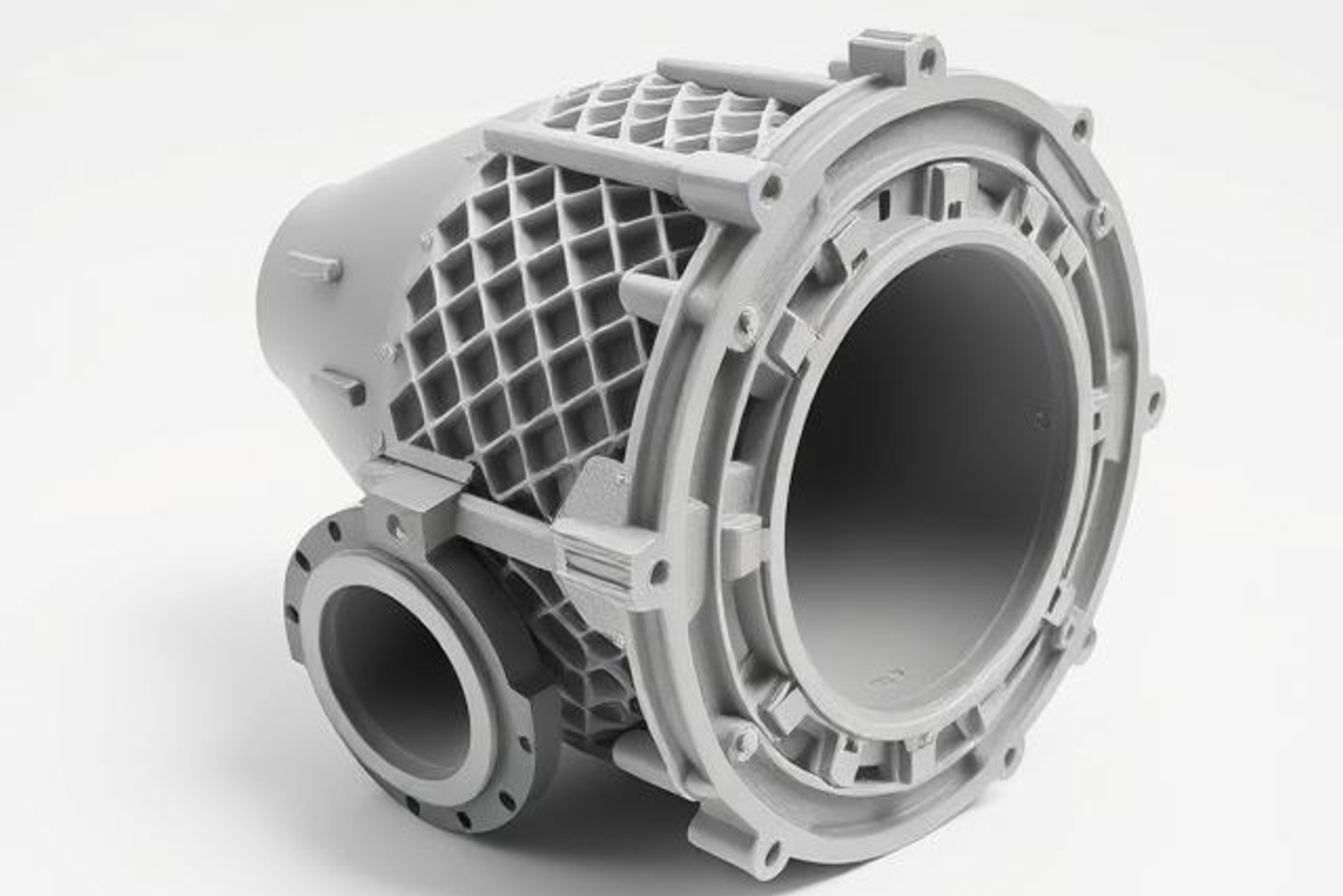

Metal 3D Printing

Stereolithography (SLA)

SLA offers high-resolution, smooth-surfaced parts ideal for visual models, masters for molding, and tight-tolerance prototypes. Perfect for complex geometries, fine details, and transparent components.

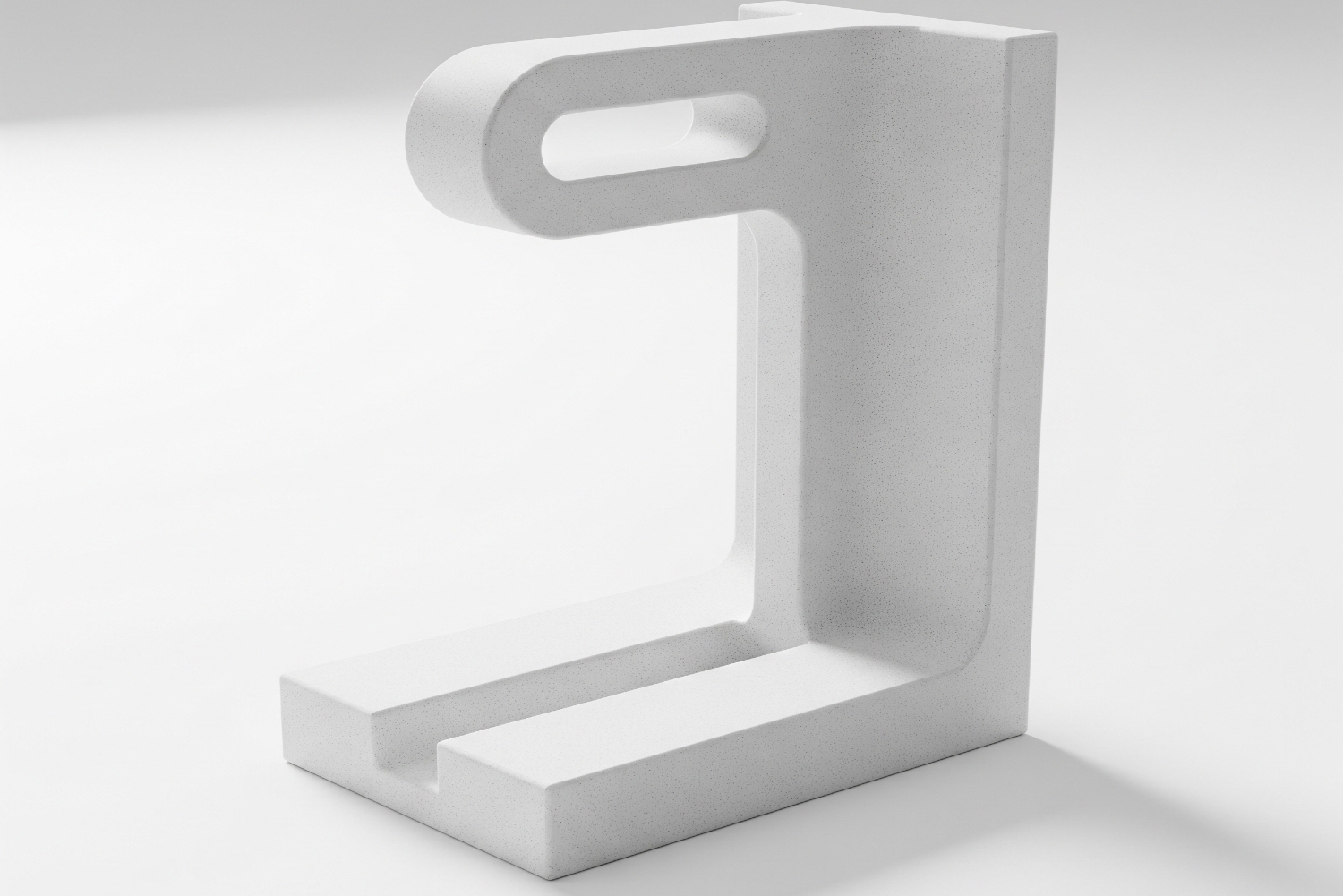

Multi Jet Fusion (MJF)

Known for its speed and mechanical strength, MJF is ideal for producing functional prototypes and production parts in nylon and other performance thermoplastics. It offers fine feature resolution and excellent surface quality.

Selective Laser Sintering (SLS)

SLS produces durable, high-performance parts without the need for support structures. It’s well-suited for mechanical testing, functional prototyping, and low-volume production using materials like PA12 and PA11.

PolyJet

PolyJet technology prints in ultra-thin layers for high-accuracy prototypes with smooth finishes and multi-material capabilities. It’s perfect for creating flexible parts, overmolds, and realistic medical or consumer product models.

Advanced Photopolymers

We offer a range of photopolymer options for enhanced strength, flexibility, heat resistance, or biocompatibility—supporting even the most demanding functional or aesthetic requirements.

Large Format Printing

Need bigger parts without sacrificing detail? Our large-format 3D printers allow for the production of large-scale prototypes, jigs, and fixtures in a single print, eliminating assembly steps and improving strength.

Quality Inspections & Validation

We ensure dimensional accuracy and structural integrity through advanced inspection and metrology tools, including 3D scanning, CT scanning, and detailed reporting. Every part we produce undergoes rigorous quality control to meet your performance requirements.

Finishing Options

Once your part is printed, we offer a full suite of post-processing and finishing services, including:

- Sanding and polishing

- Painting and dyeing

- Vapor smoothing

- CNC machining for critical features

- Assembly and packaging

3D Printing Materials

Performance Materials for Every Application

Plastic 3D Printing Materials

ABS

Known for strength, machinability, and a clean finish, ABS is widely used for general-purpose applications. We offer a range of ABS-like photopolymers, including:

- Accura Xtreme White 200

- Accura Xtreme Gray

- Accura 7820

- WaterShed XC 11122

- MicroFine

Nylon

Lightweight yet tough, with good chemical resistance and flexibility. Ideal for functional prototypes and end-use parts.

- PA 12 White

- PA 11 Black

- PA 12 Black

- PA 12 Mineral-Filled

- PA 12 40% Glass-Filled

- PA 12 40% Glass-Filled Black

Polycarbonate (PC)

- Accura 60

- Accura 5530

- PerFORM (Ceramic-like Advanced High Temp)

Polypropylene (PP)

Flexible, fatigue-resistant, and chemically durable. Commonly used for living hinges and fluid-related parts.

- Polypropylene Natural

- Somos 9120 (PP-like Translucent White)

- Carbon FPU 50

Silicone

TPU

Digital Photopolymer

Metal 3D Printing Materials

Aluminum

Cobalt Chrome

Inconel

Stainless Steel

Titanium

Industries We Serve

Why Choose Universal Prototype for 3D Printing?

At Universal Prototype, we bring together cutting-edge 3D printing technologies, expert engineering, and flexible production capabilities to deliver high-quality parts—faster and smarter. Whether you’re prototyping or scaling to production, we ensure precision, reliability, and speed at every step.

- Wide range of 3D printing technologies under one roof

- Industrial-grade materials and equipment

- Prototyping to production scalability

- Fast lead times and on-demand manufacturing

- Expert engineering support for design and optimization

- Strict quality assurance for every part